Magnetic Float Sensor

FR(reed switch)

- Level Switches

- Liquid float level sensors

Main application

Any liquids including water, oil, and chemicals

Main feature

Insensitive to process conditions such as pressure, temperature and specific gravity

Unlike other technologies, FR offers reliable measurement without being affected by temperature, pressure, specific gravity, capacitance or conductivity.

A wide range of wetted parts materials and designs available

FR is available in various materials and designs to suit virtually any applications. Besides standard materials, 316SS, PE, fluorine resin, titanium and other materials are optionally available.

High reliability and safety

Among high accuracy reed switches, only those that meet our original standards are used to ensure stable operation over the long service life.

Easy on-site service

Set points and switch directions are easily adjusted on site. (Except for flameproof or high temperature models)

Class NK (Nippon Kaiji Kyokai) certified (07A008)

Can be used to measure fuel, lubricant oil and other liquids except on the decks, bridges and cargo tanks. (Except for flameproof types)

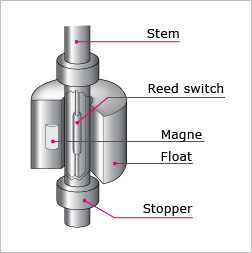

Principle of Operation

The sensor uses a magnet and a reed switch to detect liquid presence. The reed switch has its contacts encased in a glass tube with inert gas, and operates by an applied magnetic field.

The figure shows the float and the stem. The float integrates a magnet, and the stem a reed switch at the set point. The reed switch opens or closes as the float goes up or down on the stem.