Vibrating Level Sensor

VF

- Level Switches

- Vibrating solid level switches

Main application

Low limit detection of medium to large hoppers

Main feature

Flat vibration plate of 1 mm in thickness

Robust and shock resistant

Easy installation

Detection based on “pulse vibration method”

Wide sensitivity adjustable range

Fail-safe functionality

Universal power supply

Maximum 200 meter separation distance (VFS)

example

Principle of Operation

The sensor has a magnet and an electromagnet fixed on the vibration plate. When current is applied to the electromagnet, repulsive force of the magnet causes the plate to vibrate.

When the material covers the plate, vibration decreases, causing lower voltages to be induced in the electromagnet. The sensor detects the voltage change to determine material presence.

When the detector is not covered by the material

- he electromagnet vibrates at its operating frequency when alternating current is applied.

- Back electromotive force on the electromagnet becomes the largest due to change in magnetic field from the magnet

- The sensor determines the detector is not covered by the material.

When the detector is covered by the material

- Applying alternating current does not cause the electromagnet to vibrate at its operating frequency.

- No back electromotive force occurs because the magnet is stationary.

- The sensor determines the detector is covered by the material.

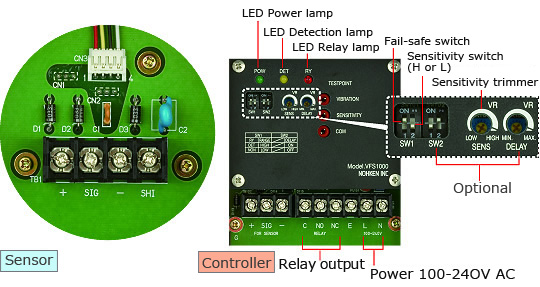

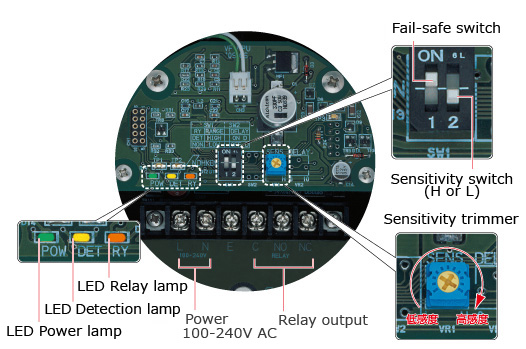

Inside the housing

Compact version

Remote version